#Industry News

Advantages of investing in BRIO ultrasonic cleaning machines for the aeronautical industry

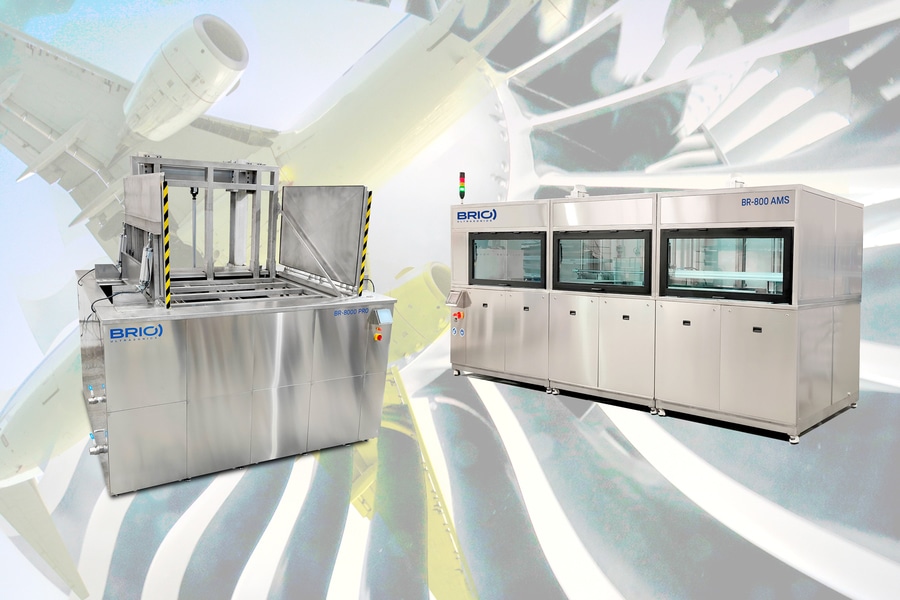

Investing in BRIO ultrasonic cleaning machines optimizes cleaning and maintenance processes, and offers significant long-term returns

The aeronautical industry demands the highest standards of cleanliness and maintenance to ensure the safety, efficiency and durability of its components. In this context, ultrasonic cleaning technology has become an indispensable solution for the effective removal of contaminants in aviation parts. Investing in ultrasonic cleaning machines not only optimizes processes, but also offers significant long-term returns.

At BRIO Ultrasonics, we are specialists in the design and manufacture of ultrasonic cleaning solutions adapted to the demands of the aeronautical sector. Our equipment combines innovation, energy efficiency and sustainability to deliver superior results in cleaning critical components. Currently, companies such as ITP Aero, Rolls Royce, Aerospace Engineering Group and Airgrup have BRIO machines for their maintenance and manufacturing processes of aeronautical components. With more than 30 years of experience, we guarantee customized solutions that optimize maintenance and extend the life of parts, ensuring the best return on investment for our customers.

- How an ultrasonic cleaning machine for aircraft parts works

Ultrasonic cleaning machines use high-frequency acoustic waves to generate acoustic cavitation in a liquid medium. This phenomenon consists of the formation and collapse of microbubbles that uniformly and efficiently release dirt, oils, carbons, polymers and other debris adhered to the surfaces of aeronautical parts. If you want to know more about the operation of an ultrasonic cleaning machine, you can see our blog article.

This method is especially effective for critical aircraft components such as turbines, heat exchangers, hydraulics, and structural parts, where conventional cleaning is not enough to remove debris embedded in complex geometries.

- Benefits of using ultrasonic cleaning machines for the aeronautical industry

· Greater cleaning accuracy

Ultrasonic cleaning machines remove dirt in micro-cavities, internal ducts and complex geometries without the need to disassemble parts, ensuring a deep and uniform cleaning.

· Reduced maintenance times

By automating the cleaning process, aircraft and equipment downtimes are significantly reduced, improving the productivity of companies in the sector.

· Operational cost savings

The use of reusable cleaning solutions and the reduction in chemical consumption minimize costs compared to traditional manual or solvent cleaning methods.

· Reduced wear and longer component life

Ultrasonic cleaning does not cause abrasion or wear on parts, preserving their mechanical properties and extending their service life, reducing the need for frequent replacements.

· Compliance with regulations and quality standards

This cleaning system meets rigorous aircraft industry standards, such as those set by the FAA and EASA, ensuring that parts are free of contaminants prior to reinstallation.

Investing in ultrasonic cleaning machines for the aircraft industry is highly cost-effective, as it improves maintenance efficiency, reduces operating costs and ensures optimal cleaning without damaging components. In a sector where safety and precision are essential, this technology is consolidated as an indispensable solution to meet the highest standards of quality and efficiency.