#Product Trends

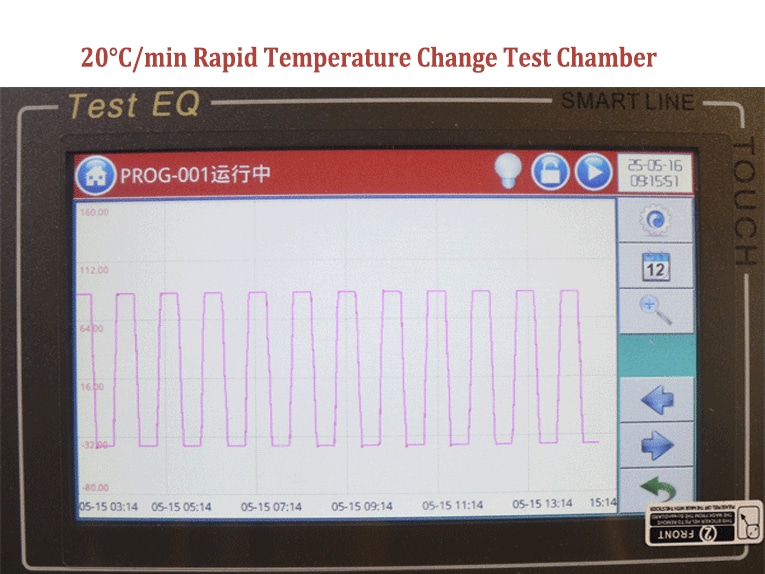

TESTEQ 20°C/min Rapid Temperature Cycling Test Chamber: Delivering Precision for Mission-Critical Applications

MIL-STD-883, ECSS-E-ST-50-13C, and JESD22-A108 for semiconductor testing

In today’s high-stakes technological landscape—spanning aerospace, satellite systems, defense electronics, and advanced semiconductor manufacturing—the demand for reliable, repeatable, and rigorous environmental testing is more critical than ever. At TESTEQ, we rise to this challenge with our 20°C/min Rapid Temperature Change Test Chamber, engineered to meet and exceed the stringent international standards that define performance, safety, and reliability in the most extreme conditions.

1. Compliance with International Standards for Semiconductor and Aerospace Applications

TESTEQ’s 20°C/min chamber is specifically designed to align with a wide range of global testing protocols, including:

MIL-STD-883H – Temperature Cycling (Method 1008.1): Ensures reliability of microelectronic devices under extreme thermal stress.

IEC 60068-2-14 – Test N: Change of Temperature: A foundational standard for evaluating device performance across dynamic thermal environments.

ECSS-E-ST-20-20C – European Cooperation for Space Standardization: For satellite and space systems requiring extreme thermal cycling reliability.

JESD22-A108 (JEDEC) – Defines temperature cycling profiles for the qualification of integrated circuits.

RTCA DO-160G – Section 8: Temperature and Altitude Testing for airborne equipment certification.

Our chamber’s 20°C/min linear rate of temperature change, with overshoot control within 1.5°C, ensures that these exacting standards are not only met but surpassed, offering superior thermal stability and repeatability.

2. High-Performance Thermal Control with Precision Engineering

What sets TESTEQ apart is the precision engineering behind our rapid temperature cycling systems. Our 20°C/min chamber features:

Linear temperature ramping without abrupt overshoot or undershoot, ensuring accurate simulation of real-world thermal stresses.

Temperature range: From -70°C to +180°C, suitable for the most demanding reliability testing of high-reliability electronics.

Advanced PID control system with real-time feedback loops to ensure thermal accuracy within ±0.5°C.

Low thermal inertia design, enabling rapid transitions and stable dwell periods.

Low residual humidity control for semiconductor and optoelectronic device testing that requires clean, stable environments.

These features are especially crucial for semiconductor reliability testing, where thermal mismatch and coefficient of thermal expansion (CTE) differences can cause latent failures in packaging and die attach.

3. Applications in Critical Sectors

Aerospace & Satellite Systems

In aerospace and satellite development, components must endure extreme temperature variations during launch, orbit, and re-entry. TESTEQ’s 20°C/min chamber allows for accelerated life testing, simulating years of thermal cycling in a controlled environment to identify early-life failures and enhance system longevity.

Defense Electronics

Defense-grade electronics must operate reliably under battlefield conditions, ranging from desert heat to Arctic cold. Our chamber’s high-speed thermal shock capability supports MIL-STD-810H, MIL-STD-461, and MIL-STD-704 testing protocols, ensuring compliance with DoD requirements.

Semiconductor and Advanced Packaging

With the rise of SiC, GaN, and high-density packaging technologies, thermal cycling has become a core part of qualification. TESTEQ’s chamber provides the precision and repeatability needed for JESD22-A108 and JEDEC JC-14 standards, ensuring that components meet the highest reliability benchmarks.

4. Why TESTEQ Stands Out in the Industry

TESTEQ is not merely a manufacturer—we are a technology-driven partner to the global aerospace and electronics industries. Our commitment to continuous innovation allows us to push the boundaries of thermal simulation:

We employ custom heat exchanger designs and high-efficiency compressors for long-term reliability.

Our chambers are modular and scalable, allowing integration into automated test lines and data logging systems.

We offer remote monitoring and control systems via Ethernet/IP, supporting Industry 4.0 and IoT-based testing environments.

With real-time data acquisition, users can track thermal profiles, failure points, and performance degradation over time.

This level of sophistication makes TESTEQ’s 20°C/min chamber ideal for failure analysis labs, R&D centers, and production QA/QC lines.

5. TESTEQ’s Vision: Powering Reliability in the Age of Innovation

TESTEQ’s mission is clear: to be a cornerstone in the global pursuit of reliability through precision environmental simulation. Our 20°C/min Rapid Temperature Change Test Chamber represents not just a product, but a commitment to excellence—a tool that empowers engineers and scientists to build safer, smarter, and more resilient technologies.

As the aerospace and semiconductor industries continue to evolve, TESTEQ remains dedicated to pushing the envelope of thermal simulation technology, ensuring our customers are equipped to meet the challenges of tomorrow’s most demanding missions.

Contact TESTEQ Today

Learn more about how our 20°C/min Rapid Temperature Change Test Chamber can support your mission-critical testing needs. Whether you're qualifying satellite components, screening defense electronics, or validating next-generation semiconductors, TESTEQ delivers the performance, precision, and professionalism you can rely on.

TESTEQ — Enabling Reliability, Empowering Innovation